NUMBERS WE ARE PROUD OF

1300

EMPLOYEES

230,000sqm

PRODUCTION AREA

> 20,000

EQUIPED GYMS

minor

COMPLAINT RATE

COMPANY HISTORY

OUR PHILOSOPHY

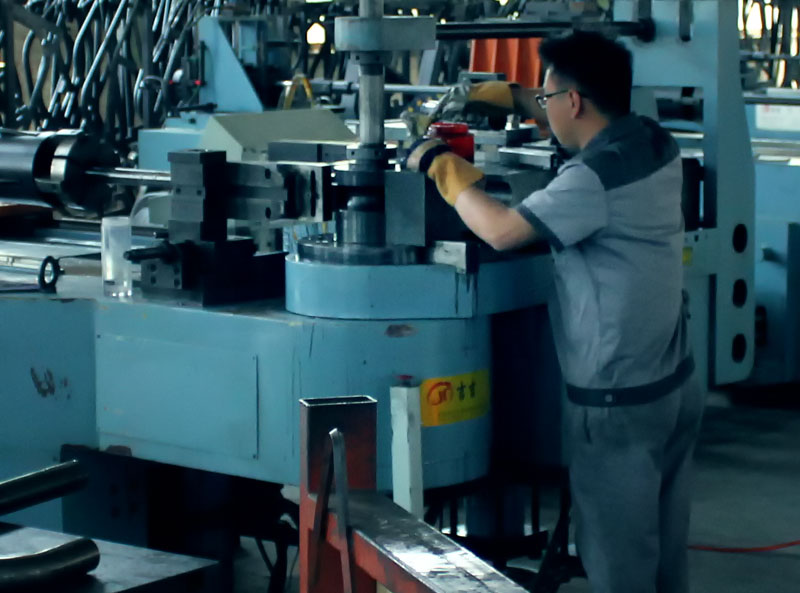

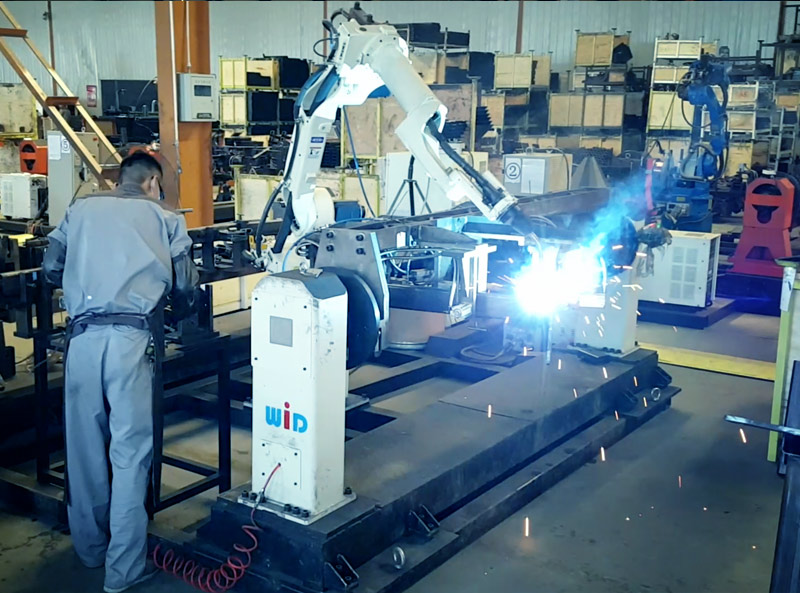

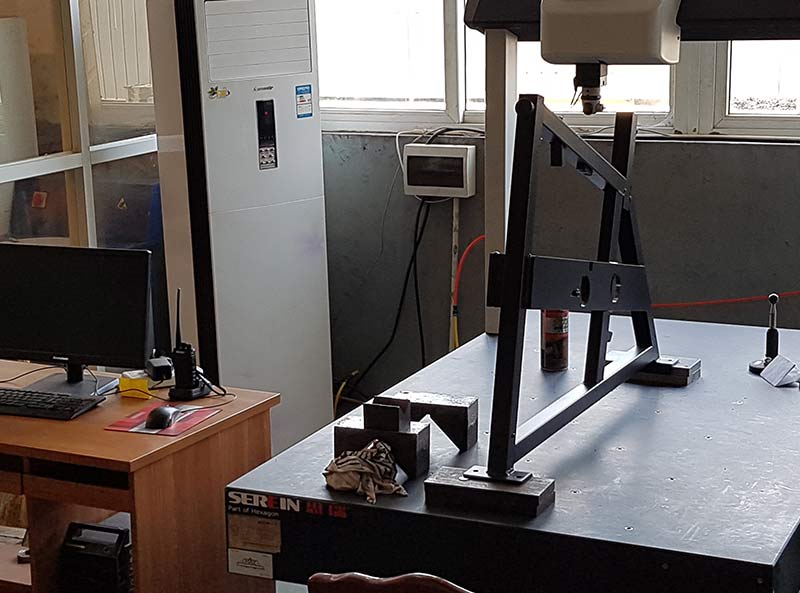

DHZ would like to supply the best price and high quality for you as the customer. In order to achieve this goal over 90% of your fitness device is produced in our own factory. This means there are no profit margins of other suppliers – all to your advantage. Likewise, the quality can be better controlled. By efficient mass production methods such as laser cutting and robot welding we can offer extremely competitive prices.

PRODUCTION CAPACITY

CERTIFICATES

ISO 9001 – CERTIFICATE

DIN EN20957/2 CERTIFICATE

CE – CERTIFICATE